ESP Components & Accessories

Rotary and Vortex ESP Gas Separators, Mingo Motor Protectors, Alternative ESP Solutions, Adapter Kits and Couplings, Shroud Hangers, Downhole Check Valve Tools

Contract Manufacturing & Fabrication

Machines and Capabilities

HVOF Thermal Spray

Plating

Surface Pumping Products

Mingo Horizontal Thrust Chambers, Surface Pump Intake Housings and Discharge Assemblies

ESP Components & Accessories

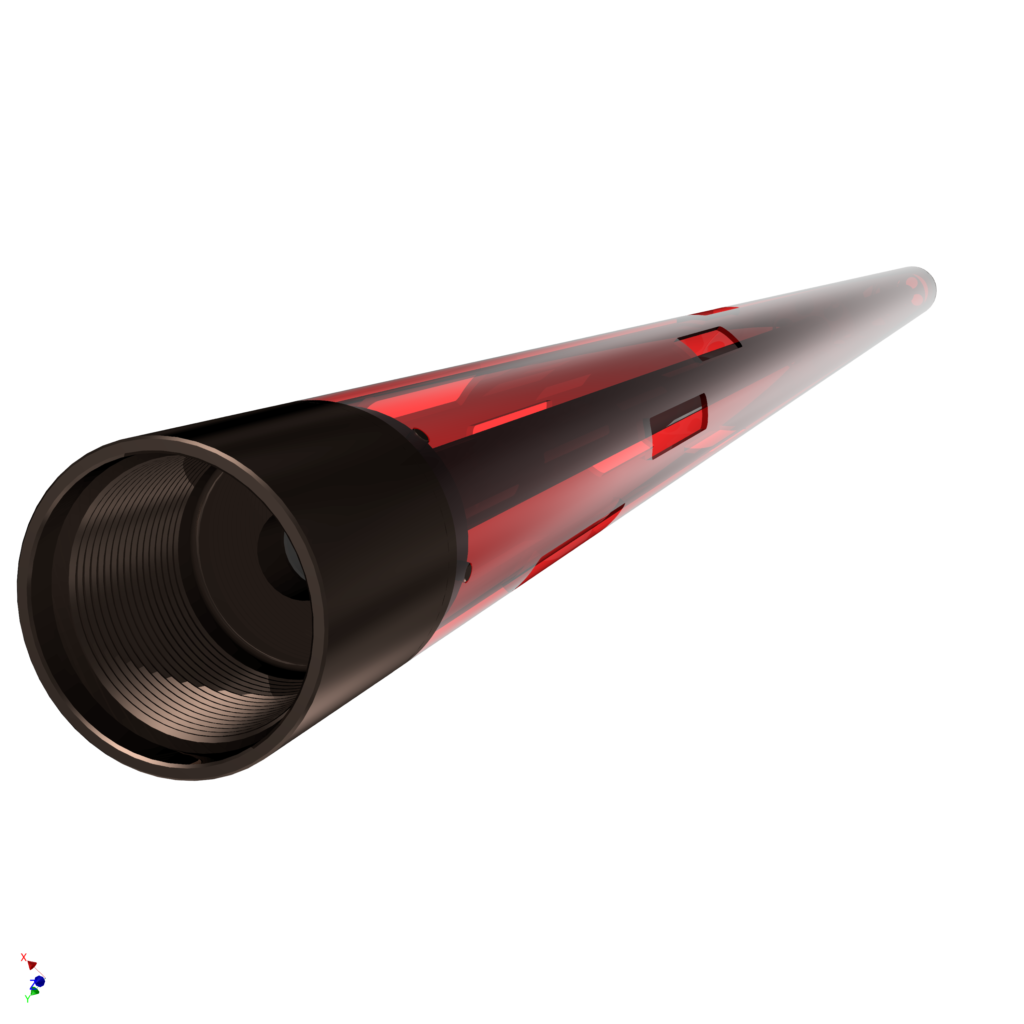

Rotary & Vortex ESP Gas Separators

Mingo has been making gas separators for more than 30 years. As one of the original designers of gas separators for the industry, our products are fully field-tested and used in downhole pump applications all over the world to effectively separate gas from liquid.

These field proven, cost effective designs are perfect for traditional applications with gas liquid ratios too high for standard pump stage volume limits. Mingo Separators are adaptable to multiple equipment providers and offered in 338, 400 and 513 series options. For added AR support, tungsten carbide shaft bearings as well as corrosion and abrasion resistant coatings can be applied.

Rotary / Vortex

2 or 3

Rotary / Vortex

2 or 3

Rotary / Vortex

2 or 3

For a complete product list contact us or request a quote.

Alternative ESP Solutions

350 RPI

Ninja Separator for Rod Pump ApplicationsNinja LCI - Liquid Concentrating Intake

The Ninja intake is a specially designed Liquid Concentrating Intake, aimed to reduce gas entrance, aid in separation, as well as provide an artificial sump within the ESP string. The Ninja can be ran with multiple ESP providers in 400 series. Mingo also offers a Ninja separator designed for rod pump applications. Available in 350 and 450 series with both 2 7/8s and 3 1/2″ EUE Connections.

Adapter Kits & Couplings

Adapter Kits

Mingo Adapters. A product that has become a staple in the ESP industry. This innovative and continuously evolving product line allows operators to mix and match OEM equipment for either cost saving or application changing needs.

Have a surface pump retro-fit project? We can help with that too. Adapter plates, couplings, modified intakes and drop in thrust chamber replacements available.

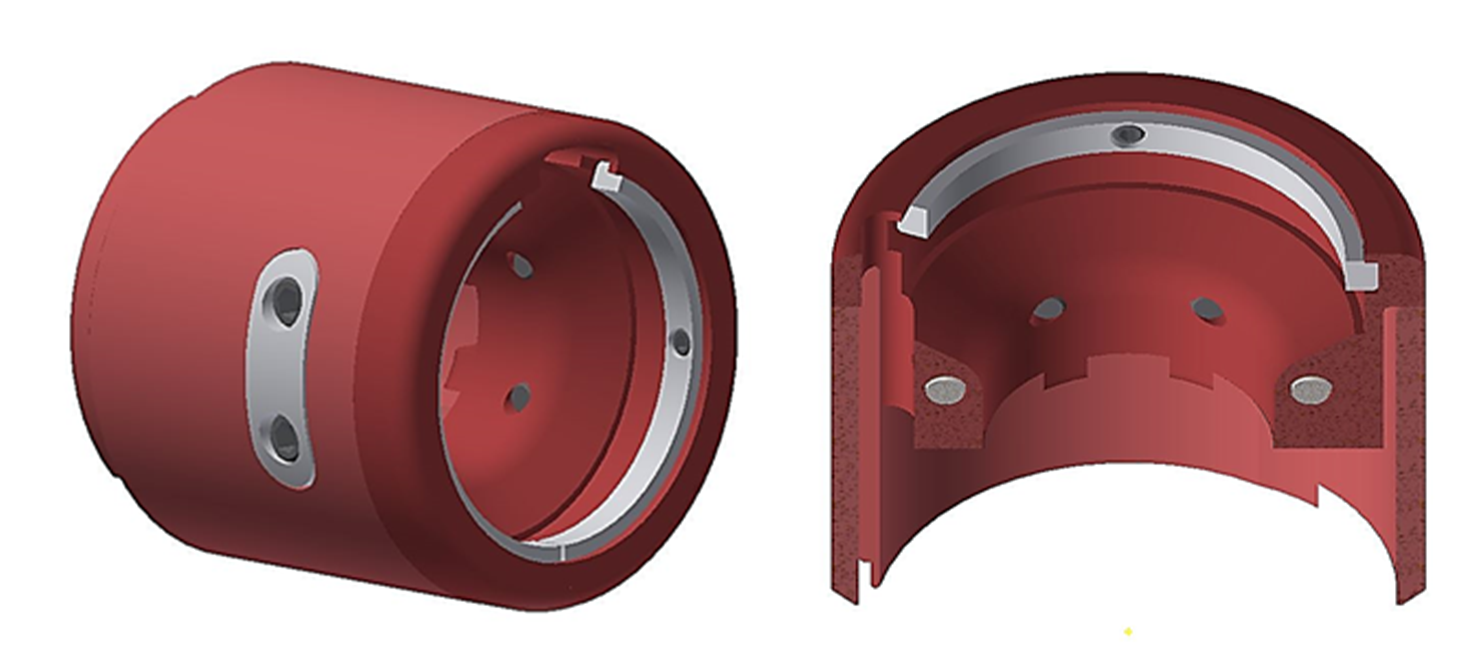

Shroud Hangers

Mingo Manufacturing’s shroud hangers offer a more rugged design than many others available on the market. Used to help cool pump motors, our shroud hangers can also be used for special applications, such as supporting a heavy weight from the pump string.

Especially in oil fields with sand problems, Mingo’s shroud hangers are the product of choice because of their sturdy design and corrosion resistance.

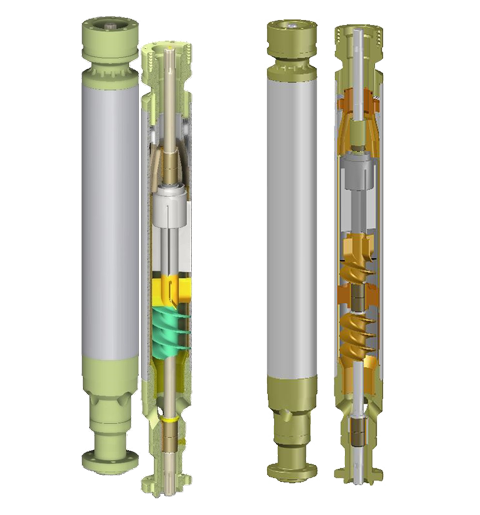

Downhole Check Valve Tools

Mingo Manufacturing has been making downhole check valve tools for over 25 years. Known across the industry as the leader in large diameter check valve manufacturing, we are also a local source for smaller, more traditional applications. Ranging from 2 3/8s to 12″ and larger in diameter, our combination check and bleeder valves stop back flow, preventing ESP back spin and allow for faster re-starts.

As with all our products, our check valves are field-tested and offer more robust design, corrosion-resistance and better performance than many of our competitors’ products. We offer different sizes and types of materials in-house and are happy to discuss custom designs.

Contract Manufacturing

A valued supply chain partner for a wide range of ESP and Surface Pump Equipment OEM’s for nearly 40 years. Our business was founded on producing the highest quality machined parts on a consistent basis.

Over 45,000 square feet of machining space with everything from manual mills to 5-axis CNC machines, welding, assembling, testing and CMM inspection.

Expert machinist skilled in items such as heads, bases, intakes, housings, shafting, couplings, and many other pump related components and accessories.

“From concept to completion”

Capability Portfolio

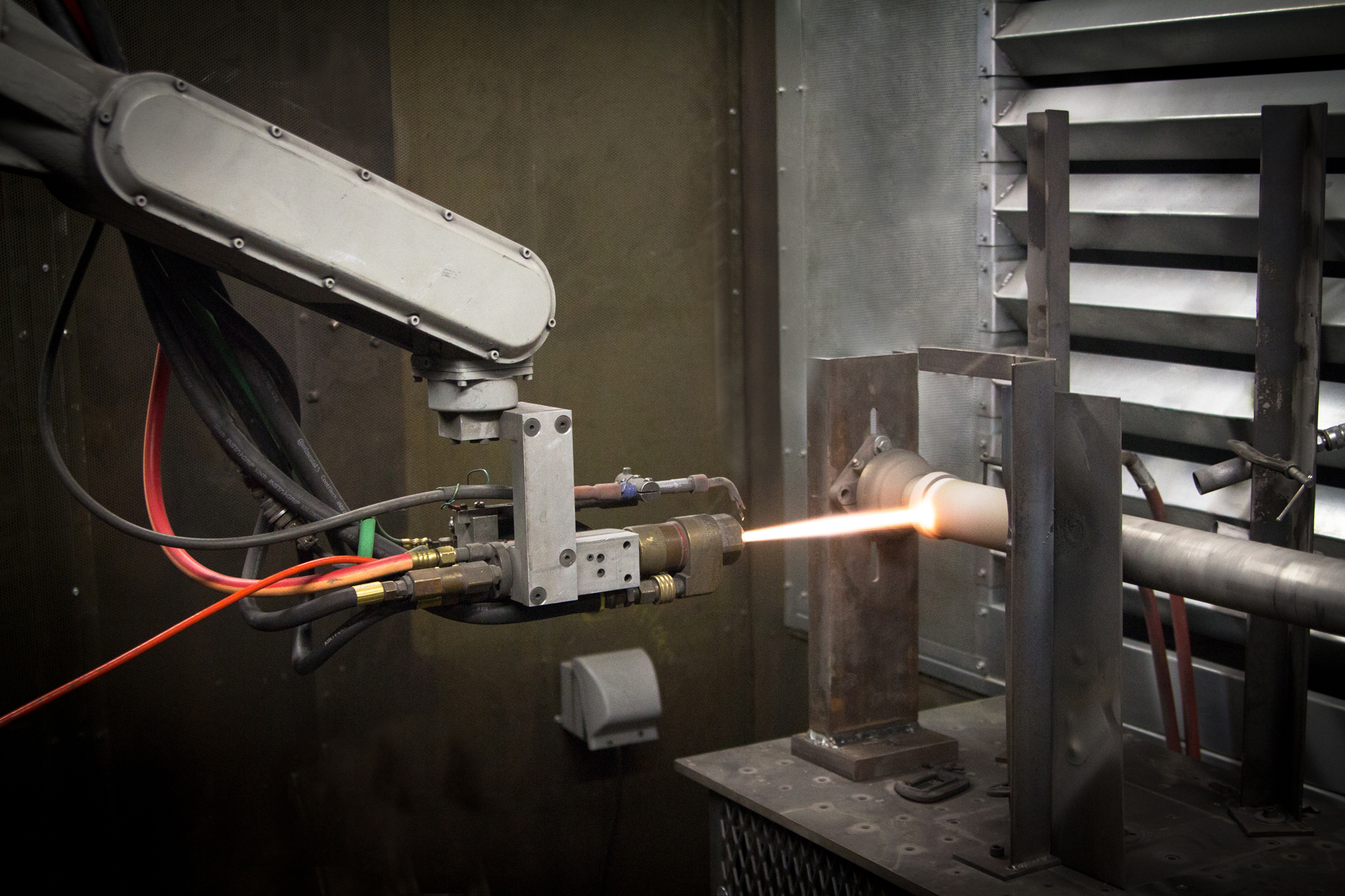

HVOF Thermal Spray

Once an adjacent company, Mingo Aerospace is a full service coating provider. Primarily serving as an aerospace industry repair facility, Mingo Aero’s products and applications can be used in many application in the oil and gas sector.

Although the two companies are separate entities now, we still leverage each others expertise to explore challenging applications and new products.

Applications- ESP stage coatings, gas separator internal components, thrust runners, balls and seats, flow tubes, etc.

Surface Pump Products

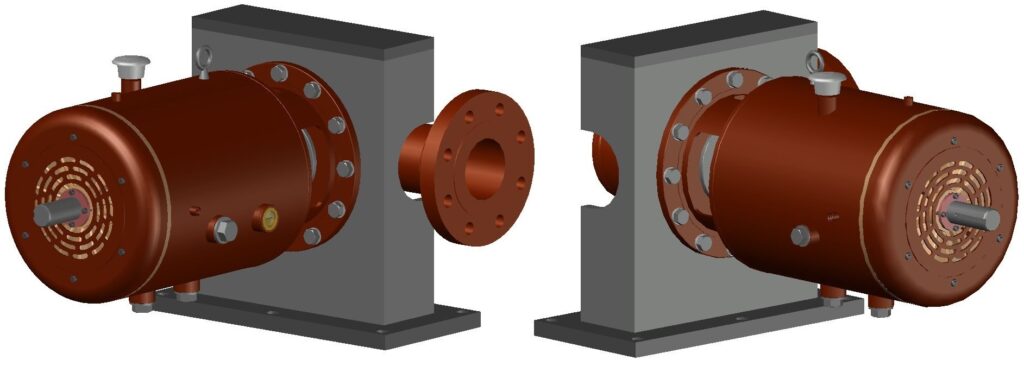

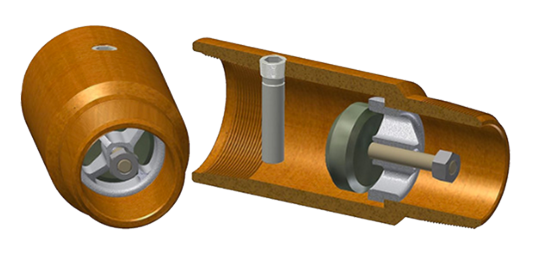

Mingo Horizontal Thrust Chambers

Mingo has been manufacturing horizontal thrust chambers for the surface pumping industry for nearly 40 years. Look closely and you will find Mingo thrust chambers on a number of major equipment providers pumping units, as we provide and private label equipment to some of the biggest names in the industry. With designs capable of handling up to 25,000lbs of thrust and over 2000hp we can build for any application.

Mingo also offers warranty backed rebuilds on most all OEM thrust chambers such as SLB G series, BHI XE series, WoodGroup, HAL, and most GE models.

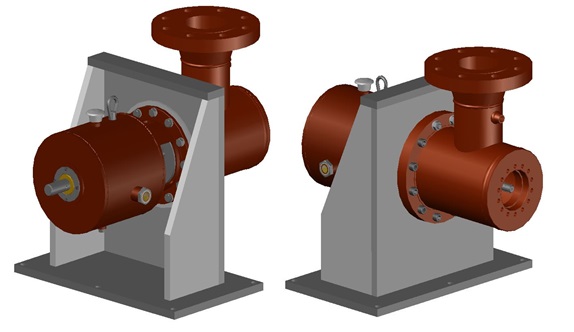

Surface Pump Intake Housings & Discharge Assemblies

Intake Housings and Discharge Assemblies

Machined and welded intake assemblies to compliment our Horizontal Pump Thrust Chamber Assemblies. In addition to our own product line, MM is the premier domestic choice for build to print suction housings. We manufacture intake assemblies for a number of surface pump OEM’s across the globe.

We also offer a complete line of ANSI style flanged discharge head assemblies. From 400 series 2” -600# and up. Certified welders and consistent manufacturing processes allow us to produce the highest quality parts and domestically competitive prices.